Welding helmets are an essential part of any welding job. They protect your eyes from harmful rays emitted during welding. However, there are different types of welding helmets. Some are designed for specific applications, while others are used for general purposes.

The DIN in welding helmets refers to the graduation standardized by the German institute. It is a series of numbers, generally, from 8 to 15, that determines the opacity of the welding shade glass.

In this blog post, I will discuss what does DIN mean in welding helmet and which one you should buy

What Does DIN Mean In Welding Helmet

The DIN in welding helmets is, technically, a number representing the degree of filtration that the glass offers. It is standardized by the DIN agency (Deutsches Institut für Normung). It is Germany’s national standards body for testing and certifying safety equipment. The scale is established between 1 and 15, with 1 being a completely transparent glass and 15 being an utterly opaque glass.

Welding helmets generally offer protection in the range between 9 and 13, which corresponds to the most common electromagnetic emissions in the field of electrical and chemical welding.

Automatic Welding Helmets

The automatic welding helmets or photosensitive shade allow the welder to work more efficiently because the crystal increases the intensity of ultraviolet emissions, the infrared and visible spectrum is automatically and immediately opaque, as detected.

The change occurs in a small fraction of a second (1/3600 in-home helmets and 1/20000 in professional helmets), so the eye is properly protected from dangerous radiation, without the need to “guess” where the electrode should be placed or the torch.

These helmets generally have an obscuration range of 9-13, so they are not fixed like traditional helmets, thereby offering useful versatility for the welder working with various techniques.

Fixed Type Welding Helmets

The helmets or helmets welding fixed type or specialized, provide complete protection for a number DIN specific; the most common are located within the range 9 – 13, although it is possible to obtain graduated helmets with greater or lesser opacity.

As a general rule, helmets and goggles designed for flame welding provide the lowest DIN numbers, while welding shades designed for techniques such as TIG in a high current intensity range are graduated up to 16.

Welding Goggles

Of all, they are the ones that offer the least protection, although they also allow greater comfort. They are designed for welding with a flame of low emission of ultraviolet radiation.

Helmets Darkening Ranges

Is it desirable or advisable to always have the maximum protection in the helmet? The answer is no. The darkening of the glass responds to the need to protect the eyes from exposure to harmful radiation, but that same protection makes vision difficult.

A flame welding does not offer the same radiation intensity as that which could cause, for example, the electric arc of a TIG welder with an output of 550A. In the first case, it is desirable to filter only what is necessary to visualize the work that is being carried out. In the other case, a good part of the visibility must be sacrificed to protect the view.

Different degrees of obscuration ( DIN graduation ) exist because each degree offers another relationship between visibility and protection. It would not make sense to work with a DIN 15 helmet for oxyacetylene torch welding. It would also be dangerous to use a grade 9 helmet to work with the TIG technique in the higher ranges of electrical intensity.

Considering the protection of the user’s eyes as a priority and the importance of visibility when executing the work, some manufacturers have designed photosensitive helmets with a built-in LED lamp.

How To Choose Which Helmet To Buy?

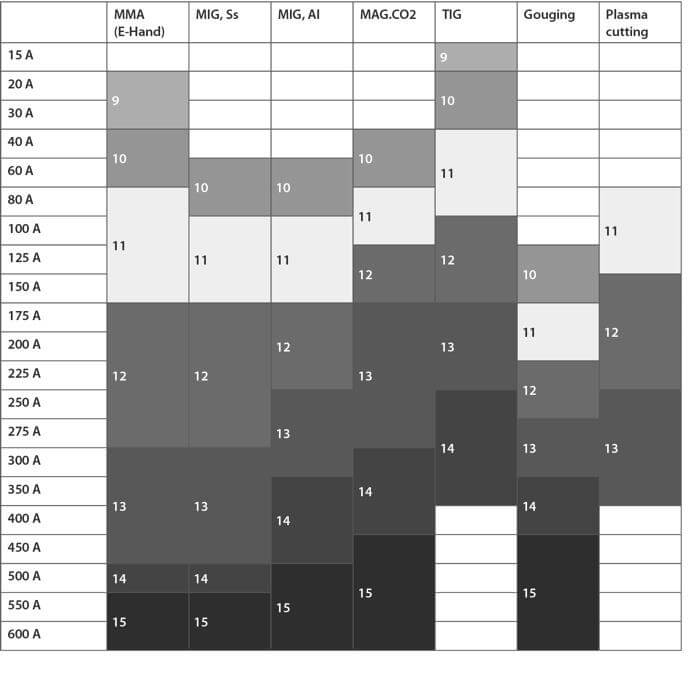

To correctly choose which photosensitive helmet to buy, always look for the DIN on welding helmets, and choose according to the table we offer below.

The following table indicates how to regulate the degree of obscuration according to the type of welding and the Amps of arc current.

For manual arc welding (SMAW) choose the ranges between 9 and 13. If you are going to work mostly at maximum intensity, choose a fixed helmet at graduation 13. On the contrary, if your work will be variable, choose an automatic photosensitive helmet within this range; they are the cheapest since they are mass-produced and are the most preferred.

For welding with the MIG technique, starting from a protection grade 10 up to grade 13. For TIG, on the other hand, it is necessary to use the maximum protection available when working at high intensities.

In plasma cutting, choose automatic helmets with a minimum graduation of 11.

It is possible to work with more minor graduations for plasma welding, starting from DIN 6 and going up to DIN 11.

As a general rule, the higher the current intensity – if working with electric welders – the greater the protection chosen should be. The range varies according to the technique, the filler material, and the material to be welded, so it is not possible to generate a simple equation for choosing the degree of DIN protection, but it is possible to state that, for most of the In cases except the TIG technique, protection within the range 10-13 is adequate.

Suppose you want a versatile helmet for home, hobby or small production jobs. In that case, an auto-darkening helmet within the 9-13 range is definitely the best choice, both for the low price and the product’s reliability.

If your job specializes in TIG techniques with high currents, choose fixed graduation welding mask in the higher ranges, starting at 13.

For flame welding, protection within the range of 6-11 will suffice.

Conclusion

In conclusion, according to your application, choose the helmet to buy. The important thing is that you always use adequate protection to work safely, avoiding irreversible damage to your eyesight.

Leave a Reply